Clear Cylinder Tube Machine Mode Installation (11~15 step)

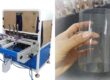

11. Determine the Width of the Material Storage Rack

- Adjust the sheet feeding guide rod at the rear end of the equipment to the left according to the position of the sheet edge positioned in step 14.

- The transverse guide rod at the end close to the moldof clear cylinder tube machine is the reference guide rod and should not be adjusted casually.

- Loosen the positioning screws of the transverse guide rod, two on each side, four in total.

- Adjust the distance between the second transverse guide rod and the first transverse guide rod according to the width of the material.

- Ensure that the material can move slightly back and forth between the material storage racks. That is, the distance between the two guide rods should be 1 to 2 mm wider than the material.

- Lock the positioning screws of the transverse guide rod.

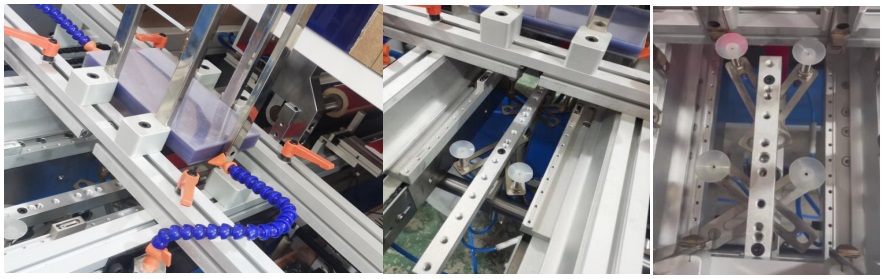

12. Check the width of the material at the rear end &lock sheet feeding guide rod.

- Loosen the positioning screws of the longitudinal guide rod, two on each side, four in total.

- Observe the position of the edge of the sheet material below the mold of clear cylinder tube machine from the end of the material storage rack.

- Move the longitudinal guide rod so that the inner corner edge of the rod is close to the edge of the corresponding side of the film sheet.

- Ensure that the values displayed on the transverse guide rods at the intersection positions of the two transverse guide rods and the same longitudinal guide rod are consistent.

13. Set the material taking point

- This step is to set the position of the material taking point for the cylindrical product, and the following points need attention:

- The height of the formed cylinder must be smaller than the length of the mold. The maximum forming height of this equipment is 390.

- In order to obtain a uniform downward pressure of the cylinder, try to place the material at the center position of the clear cylinder tube machine

- Therefore, the material taking point needs to be close to but not beyond the position of the right edge of the material.

- Take the forming of a cylinder with a height of 130 as an example, the material taking point can be set as 130 or 140. (It is better to round the number.)

- For the convenience of subsequent operations, after setting the material taking position, the position of the material taking point can be marked on the mold.

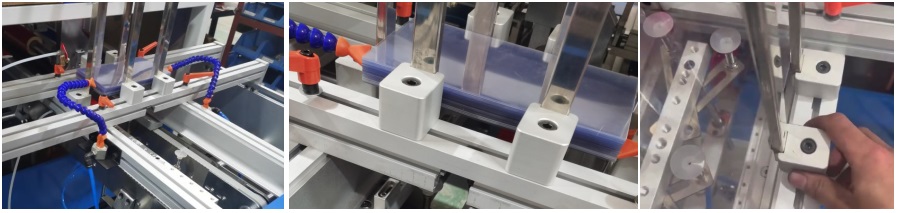

14. Adjust the Spacing of the Upright Poles on the Material Storage Rack

- The material storage rack is enclosed by 6 to 8 retaining strips of the material storage rack. Therefore, a total of 8 retaining strips of the material storage rack are randomly delivered.

- For materials with relatively short dimensions, 6 retaining strips of the material storage rack are used. For materials with relatively large and long dimensions, 8 retaining strips are used.

- In order to ensure that the materials are reasonably supported and the materials can be fed in parallel. try to arrange the retaining strips of the material storage rack evenly according to the length of the edge of the sheet material.

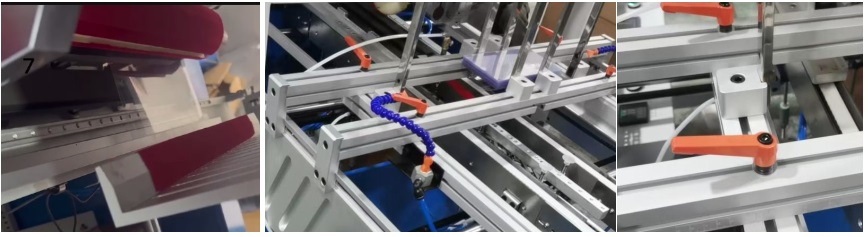

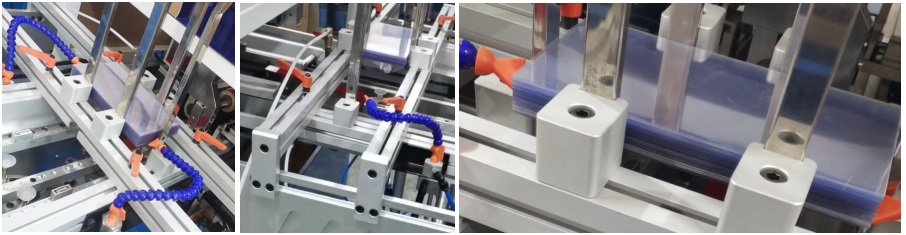

15. vacuum suction cups

- The clear cylinder tube machine is equipped with a total of four vacuum suction cups. You can use either two of them or all four together.

- When producing small-diameter and short cylinders, you can stop supplying air to the two rear vacuum suction cups to obtain sufficient suction force.

- When switching to producing large-diameter or tall cylinders, reconnect the air hoses of the two rear suction cups and evenly place the suction cups below the material.

- The placement position of the vacuum suction cups should maintain a certain distance from the edge of the main guide rod to prevent collisions.

- Try to place the vacuum suction cups close to the middle position of the line connecting the four sides of the material and the center point of the material.